Heat resistance is the ability to resist and remain unaffected by heat. Heat resistant coatings offer protection to components that are exposed to extreme temperatures or severe temperature fluctuations. The coatings are designed to protect components against heat whilst operating to high performance levels in challenging environments.

Few fluid lubricants are recommended for use at cryogenic temperatures (most become solid) or above 400°F/205°C (they oxidize rapidly). Most Xylan® dry-lubricant coatings, however, operate comfortably at both extremes. They retain their hardness at high temperatures because most binders for these coatings are thermoset engineered polymers. Xylan coatings also operate effectively at extremely low temperatures (down to -420°F/-250°C).

For temperatures above 500°F/260°C, Xylar coatings, specifically designed for use in industrial environments are designed to withstand high-heat service temperature exposure up to 1000°F/550°C. These coatings provide excellent thermal shock, good corrosion and oxidation resistance.

When a substrate operates to extreme temperatures and fluctuations it can result in the breakdown of the surface, corrosion and component failure. Heat-resistant coatings offer protection without losing functionality.

There are various types of heat resistant coatings:The substrate that the coating is applied to, the application process and the end use of the component are key factors in a coating choice.

Chemical resistance is the extent to which a material can maintain its resistance to chemicals – protecting against chemical attack or solvent reaction, determining a material’s resistance to corrosive environments.…

Read More +

Abrasion resistance is the process of rubbing away the surface of something; wear means to become thin and disappear after repeated use or rubbing. The abrasion and wear of metal…

Read More +

Our laboratory suites include complete chemical testing and analysis equipment for a wide variety of industries, using a unique combination of analytical capabilities, equipment, technical expertise and quality systems. Specific…

Read More +

Dry-film lubricants are materials that reduce friction between two mating surfaces, sliding against each other without the need for oils and greases. The low friction characteristics result from the molecular…

Read More +

Friction occurs when two surfaces slide against one another, measured by the amount of drag (force) that takes place. Friction causes heat, wear and loss of energy in dynamic applications.…

Read More +

Noise and vibration reduction is an essential component of modern day design. The use of PTFE and other Whitford coatings provide a low coefficient of friction that prevents the scoring,…

Read More +

Nonstick or release is the inability of substances to adhere to a coated surface. Commonly associated with cookware and the release of food materials, non-stick and release properties are also…

Read More +

Whitford’s high-performance coatings can be found in many market sectors – wherever a functional or protective coating is required the chances are you will find a Whitford coating! Garden Tools…

Read More +

Whitford’s extensive experience within the coatings industry and commitment to responding to our customers’ needs is not only true within the markets in which we have traditionally operated but also…

Read More +

Our coatings, specifically designed for use in the Small Electrics market offer a range of price points and solutions to improve the product performance and appearance of a range of…

Read More +

Our range of textile products provide an assortment of performance enhancements including improved comfort, extended life expectancy, reduced energy consumption, and other characteristics depending on the needs of the application.…

Read More +

Offering daily support to OEM’s and their tiers, our high-performance coating ranges bring performance improvements such as abrasion resistance, low controlled friction and long-term durability. Recent developments have produced advanced…

Read More +

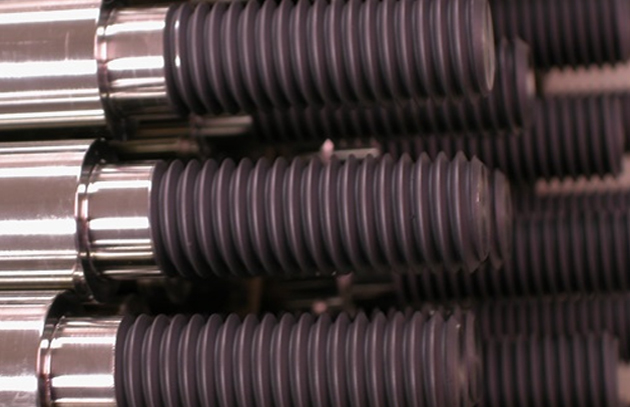

Our energy business uses advanced polymer technologies to produce a broad portfolio of coatings, formulated to perform under extreme and aggressive oilfield conditions. With increasingly demanding environmental standards and harsh…

Read More +

Our work within the energy marketplace has evolved over recent years to focus on the generation of Renewable energy. Renewable energy forms part of our global approach to reducing carbon…

Read More +

Our coatings, specifically designed for use in the Bakeware market have high release/nonstick and abrasion resistant properties, created in response to the conditions and specific uses they endure. Whether a…

Read More +

Our PFOA-free coatings, specifically designed for use in the Cookware market are available in traditional and ceramic coatings, for both interiors and exteriors.. We offer a range of tailor-made interior…

Read More +

We work closely with housewares manufacturers, coaters, retailers and end users to solve problems and fulfil specific requirements within the fast-paced housewares industry. Our decorative coatings specifically designed for use…

Read More +

We sell and provide coating service for all types of industrial bakeware. We offer a variety of one-, two- and multicoat systems with a broad range of problem-solving properties. These…

Read More +